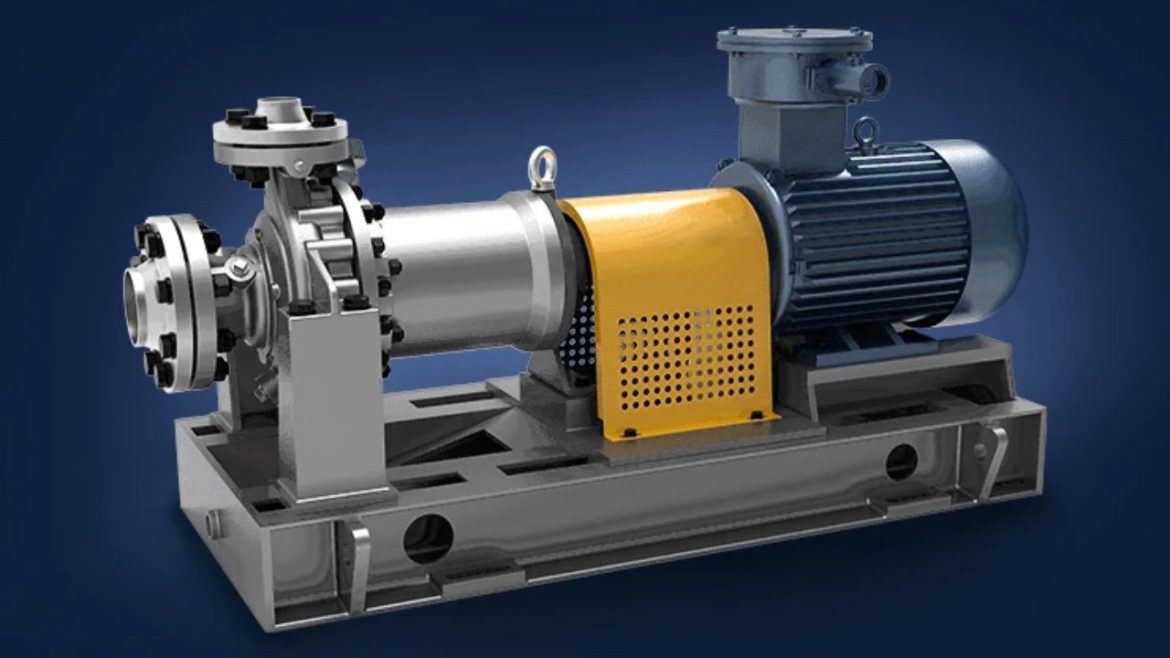

In the industrial manufacturing sector, choosing equipment means focusing on reliability, efficiency, and safety. The petrochemical, fine chemical, and pharmaceutical industries rely on pumps. It is because they must be accurate and durable. Many people trust GTC when it comes to providing such equipment. More and more top manufacturers worldwide are deciding on GTC for their pump requirements, and the reasons are just as obvious as the liquids their pumps handle. Learn more about GTC Pumps and discover why industry leaders trust our solutions for reliable, leak-free fluid handling.

Advanced technology for Magnetic Drive Pumps

GTC’s main achievement is built on its own line of magnetic drive pumps. Zero leakage is the basic promise behind these pumps. Unlike other pumps, GTC’s magnetic drive pumps seal completely, so they are perfect for working with liquids that are dangerous, corrosive, or valuable. It is especially helpful for industries where even a little leak can result in huge financial, safety, or environmental problems.

The magnetic drive pumps from GTC are designed to surpass the strict standards set by API 685 and ISO 15783. They guarantee that the pumps can handle the toughest situations, such as high pressure and high temperatures. Any manufacturer concerned with safety, following the rules, and making products last will prefer high-specification items.

Made to Last and Be Dependable

Durability and the ability of their pumps to last for years are other major reasons why top manufacturers choose GTC. The engineering team at GTC works hard to boost the Mean Time Between Failures (MTBF), which is very important for industrial operations. Clients find that GTC pumps lower their total costs due to their longer life and lower upkeep.

The key to this reliability is having top technology and strong design. Each pump is designed to address particular challenges, such as working with corrosive chemicals, fluids with many solids, or very high or low temperatures. GTC’s BM-F series is designed for thermal oils up to 450°C, and the BMR model can manage fluids with up to 50% solid content, which is better than most slurry pumps.

Industrial Automation Solutions for Specialized Applications

GTC stands out to manufacturers because it can deliver custom solutions. Industrial processes are not usually designed for every situation. The GTC pump line covers many different installations and uses, including those with self-priming, submersible, vertical, and horizontal options. For people who need high flow, high head, low NPSHr, or can pump thick fluids, GTC offers the ideal pump.

For example, the BMO II multi-stage pump can meet the high head and high flow needs, but it does this by running at a low rotational speed and having low NPSHr, so cavitation is prevented and the equipment lasts longer. The BMX series is suited for pumping thick liquids and has the powerful ability to prime itself up to 9 meters. For manufacturers who cannot tolerate any process delays or drops in performance, these technical points are vital.

Successfully Operated in Demanding Industries

GTC has earned a good reputation by being involved in large industries such as petrochemicals and pharmaceuticals. Since failures in these areas could result in legal, financial, and environmental issues, these sectors need both high performance and absolute reliability. Many case studies and loyal customers testify that GTC pumps are always up to the job.

Because contamination must be prevented in pharmaceutical manufacturing, the absence of leaks in magnetic drive pumps is very valuable. Moving aggressive fluids safely and consistently in the fine chemical industry improves both safety and productivity. GTC’s products are vital parts of important production systems.

Focus on Excellence and Customer Care

GTC gives you more than just a pump. The company ensures that its products are of high quality. Along with that, they provide helpful customer service. GTC supports the customer from the beginning of the process to after installation, acting as a partner instead of only a supplier. Because of this approach, many manufacturers trust the company for both excellent products and dependable cooperation.

Additionally, GTC’s ODM capabilities make it possible for them to design and build equipment for specific uses, something not common in the pump industry. As a result, GTC is preferred by businesses that require specific processing or have their own unique systems.

Conclusion

Because performance and dependability are crucial for a company’s profit, leading manufacturers look to GTC for their pumps. Thanks to advanced magnetic drive technology, many models for tough applications and a strong focus on customers, GTC is a leader in the fluid handling industry. For companies that rely on top quality in every area, GTC gives them pumps and the confidence that comes with them.